The evaluation criteria for finished stone products should include multiple aspects such as stone particle size, mud content, and whether there are edges and corners. The mud content of stones should be minimized as much as possible. For impurities in stones, stone cleaning equipment should be selected. The specification of stones should have a moisture content of about 2%, and the content of finished sand should also be within a certain range. For the particle size of finished sand, refined sand machine equipment should be used. For the particle size of finished sand, refined sand machine equipment should be selected; The process of cleaning stones with stone cleaning equipment is as follows: sand enters from the inlet channel, driven by an impeller, and grinds against each other to remove impurities covering the surface of the stones. At the same time, the water vapor layer covering the sand is destroyed to facilitate dehydration and obtain relatively clean stones. If the cleaned stones are not clean enough, they need to be cleaned again. Each system of the stone washing machine needs to be equipped with a complete storage hopper, bracket, conveyor mechanism, etc. The material is first transported to the storage hopper, and then the conveyor mechanism is started to transport the material to the storage hopper through the conveyor belt. The same discharge system is also important, including the discharge conveying mechanism and bracket, which can quickly send the cleaned stones out through the conveyor belt.

The washing operation of stone cleaning equipment can prevent blockage of equipment such as silos, chutes, funnels, and crushing screens, which can reduce the processing capacity of the crushing screens. When the blockage is severe, production cannot proceed normally. Extract concentrate; Some ores can be enriched with useful minerals through washing, resulting in qualified concentrates, such as sedimentary manganese ores, apatite ores, iron oxide ores, etc. Smelting limestone can improve the quality of slag by washing ore, thus meeting the smelting requirements, such as Chuanshan Limestone Mine and Wulongquan Limestone Mine.

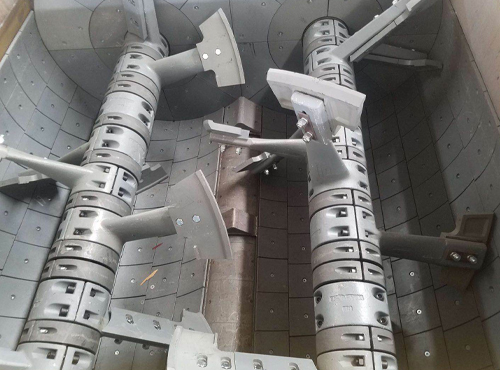

There are four main types of stone cleaning equipment: drum stone washing machine, spiral stone washing machine, vibration stone washing machine, and bucket stone washing machine. This product is mainly used in the construction of high standard projects such as highways, railways, bridges, and tunnels, as equipment for cleaning sand and gravel. Compared with similar products in China, it has the characteristics of easy mobility, large processing capacity, good cleaning effect, and energy saving. Suitable for washing fine and coarse particle materials. This utility model has a reasonable structure, easy maintenance, large processing capacity, low power consumption, and high cleaning cleanliness. The new sealing structure, new transmission shaft device, and adjustable water tank ensure the high efficiency, durability, good cleaning and dehydration effect of this series of products, and maintain stability for small particle products.

There are many types of stone cleaning equipment, and when purchasing a stone washing machine, we need to consider which one we want to buy and how to determine the model of the stone washing machine we want to purchase. We can achieve these two points by: first, selecting equipment that can clean our materials based on the particle size of the stone washing machine; second, determining the model, model, and quantity of the stone washing machine based on the cleanliness and output of the product.

Address: No. 818, Jingshi Road, Jinan, China

Tel: 0086-531-87453566

Fax: 0086-531-87453566

Postal Code: 250306

Email: sdjkgroup@163.com

jianke3566@163.com